Film Perforating:

Lidding. Vertical & Horizontal RollStock

IN HOUSE NEEDLE PERFORATING & MACRO HOLE PUNCHING

We offer perforation technology on lidding films , overwrap, and many types of vertical and horizontal Rollstock . Applications vary from controlling respiration in produce to effecting moisture retention and escape in hot applications. With the correct hole size and frequency we can actually crisp products when heated or microwaved.

The Platinum Packaging Group’s various perforation technologies means we can offer a sophisticated solution for extended shelf life, steam release gas or water vapor transmission rate control.

Min hole Size 125 to 175 Micron / Max 1500 Micron Approx.

(Holes size can depend on type of flexible packaging film, gauge, temp, running speeds and settings of perforating machine. Above sizing is approx.)

Current Needle Holes Pattern Available are 30 and or 60 Holes Per Sq.” We have 2” and 4” Wide Perf Collars (60 holes 2” and 4” collars. 30 holes only 4” collars)

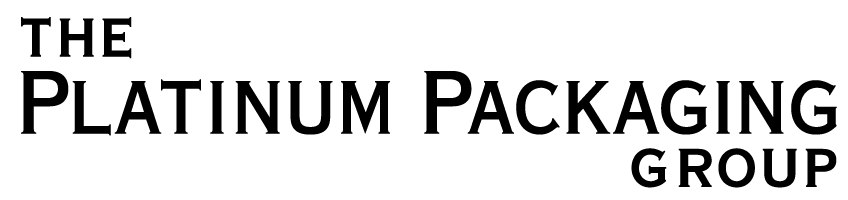

Good Perforated

Shows a perfect circular hole that adds strength and prevents tearing in mylar packaging. Tensile strength can be doubled.

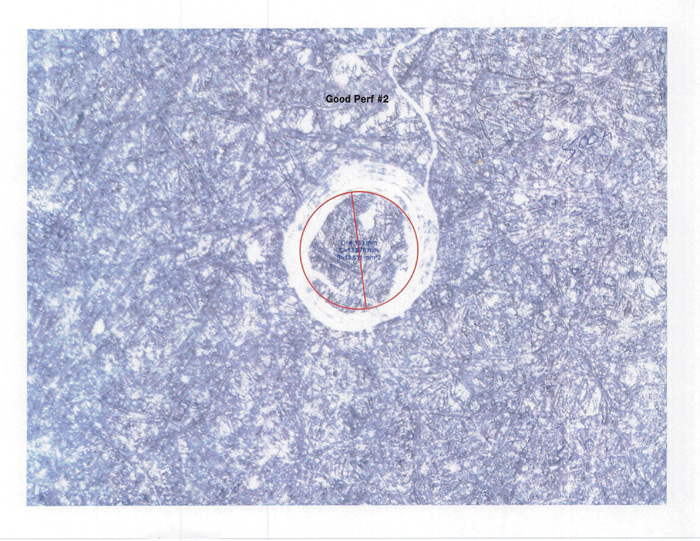

Bad Perforated Hole

Elongated hole that leads to weakness in the film sub straight

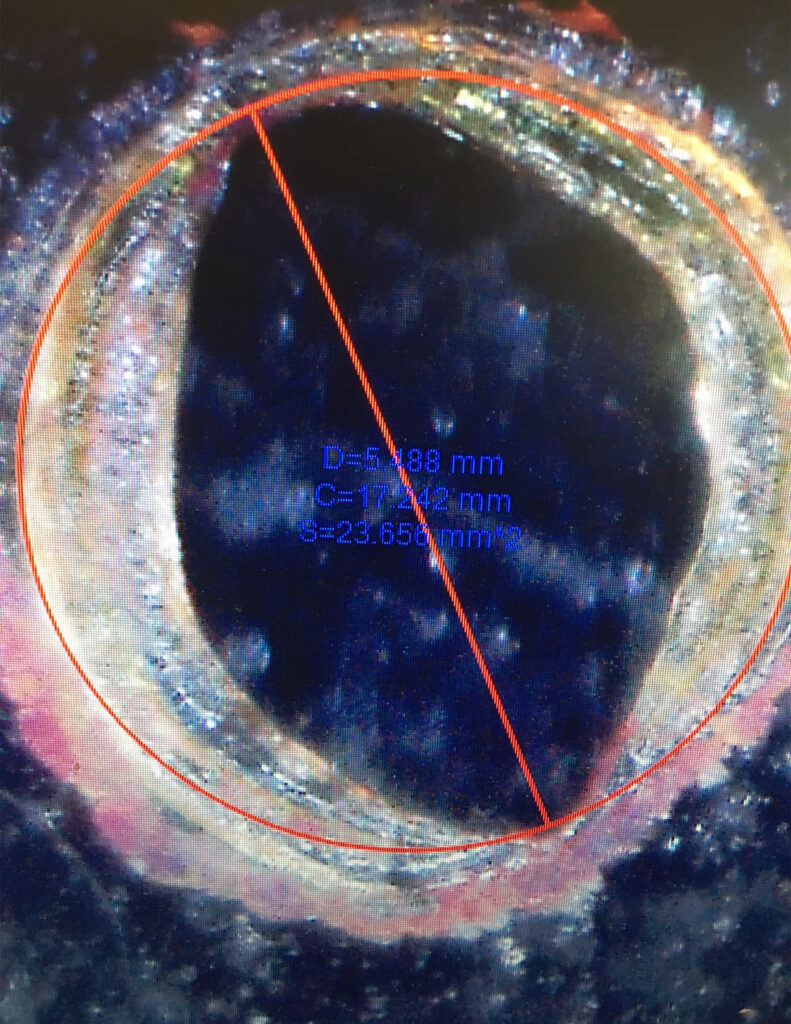

5.488 mm Registered Hole

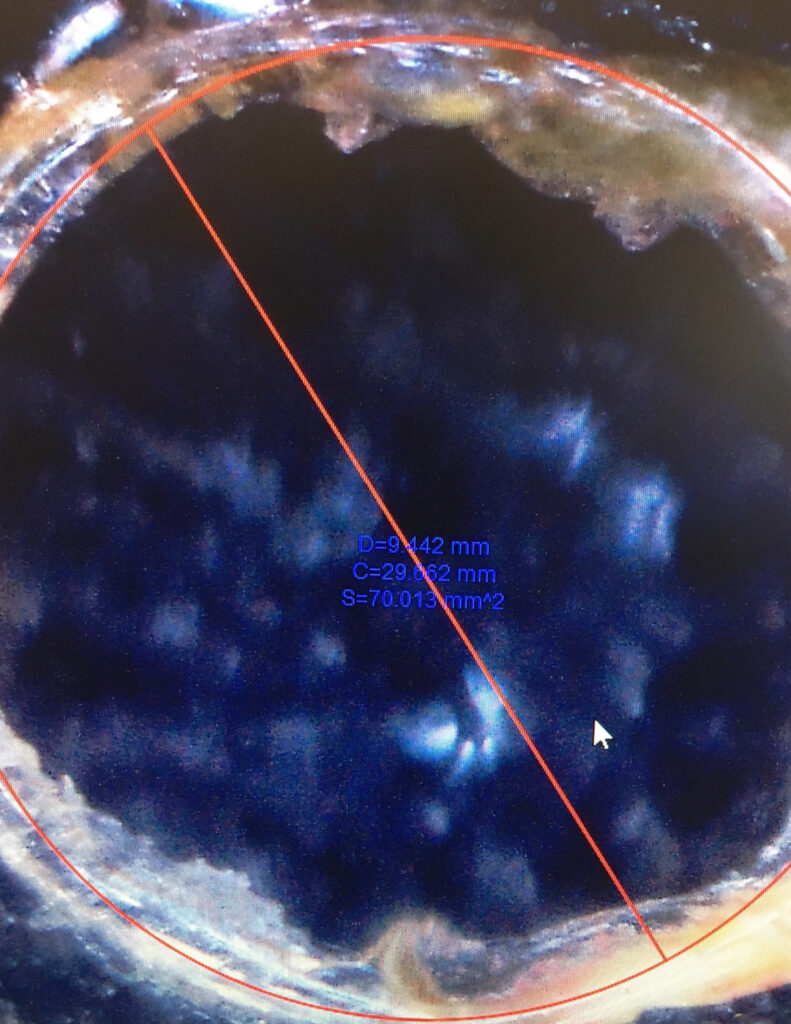

9.442 mm Registered Hole

For Hole Macro Punching , we offer a pattern of ¼” to 1/8” in diameter.

We electronically can center the pattern location.

Platinum’s laser perforation technology works at high speed and produces a very closely controlled pattern of microscopic holes in the film, exactly tailored for the application. This is ideal for produce applications or where we need to control the interior atmosphere of a package.